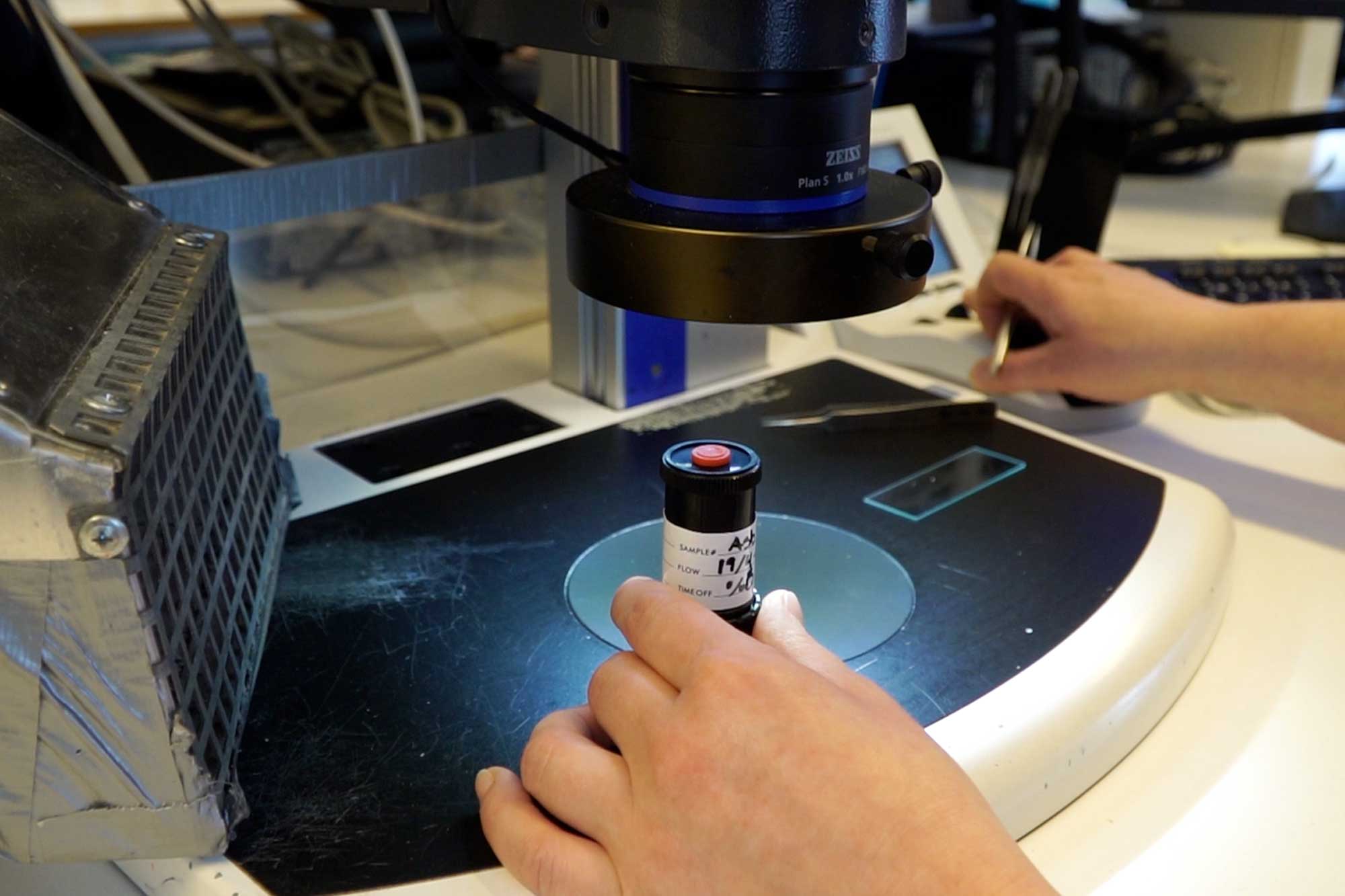

harmful fibers and other

historical dust in the air even

after thorough vacuuming?

workers inhale asbestos

and mineral wool fibers and other

historical dust.

reduces the number of fibers in the air

with up to 97% for at least 12 months

Fiberbinder® is water soluble and

allowing the construction to breathe.

practice and in laboratory tests, and

the effect is well documented.

no labeling obligation, harmful to

health or environmentally

problematic substances.

applied be quickly and easily

applied with a battery-powered

backpack sprayer.

solution on a major work

environment challenge.

FiberbinderMethod® and makes it a

lot easier to prepare quality assurance

documentation.